Transform your brand vision into high-performance commercial kitchen solutions.

As a leading manufacturer with professional expertise, TZY specializes in providing customized OEM and ODM production services for global brands.

We specialize in OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services for commercial kitchen equipment, offering tailored solutions to meet the unique needs of restaurants, hotels, catering businesses, and foodservice operators worldwide. From initial design concepts to final production, our team ensures high-quality, durable, and efficient kitchen solutions that comply with international standards.

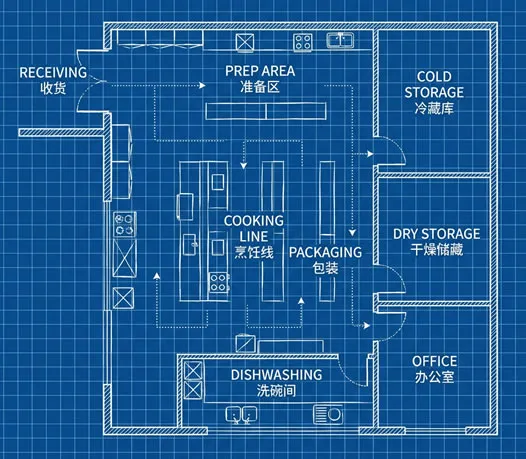

Precision Kitchen Planning, Scientific Layout

Every restaurant has unique operational needs. Our professional team will tailor the most efficient kitchen layout plan based on your restaurant's size, cuisine type, workflow, and staff count. Through scientific planning, we optimize operational flow to boost serving efficiency while minimizing wasted space, ensuring every inch of your kitchen delivers maximum value.

Our professional design team combines the international kitchen work triangle principle with HACCP food safety standards to tailor highly efficient layouts for restaurants, hotels, school cafeterias, and corporate kitchens. Through 3D visualization design, we optimize kitchen workflow, reduce cross-contamination risks, and boost meal service efficiency by over 30%.

Space Utilization & Compliance Assurance

Compliance Design: Strict adherence to local health, fire safety, environmental, and building codes ensures smooth regulatory inspections.

Workflow Optimization: Scientific planning of ingredient storage, prep, cooking, serving, and cleaning zones based on menu structure and customer flow.

Equipment Integration Planning: Pre-design water, electricity, gas points, exhaust systems, and fire safety facilities to avoid costly retrofits.

User Experience Highlights

Provide complete construction drawings, equipment lists, and detailed budgets for full project progress and cost control. Successfully delivered planning solutions for over 200 food service establishments.

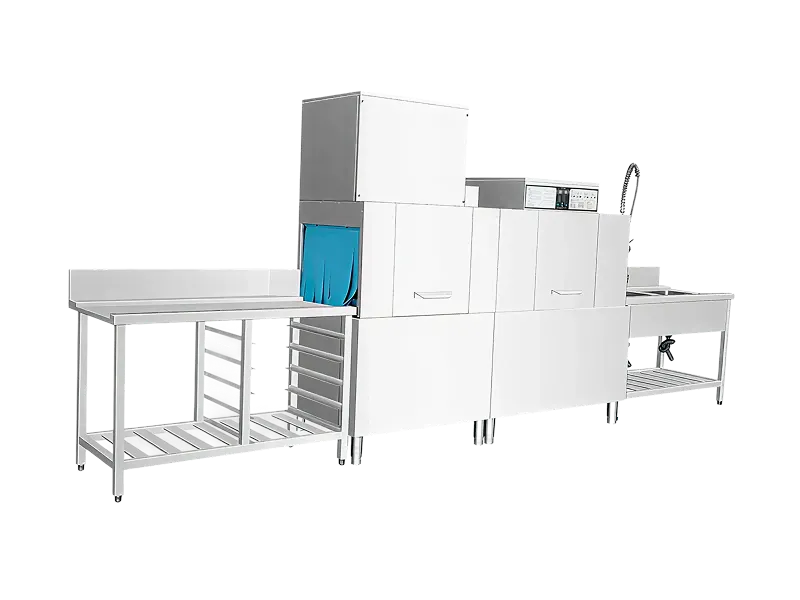

Professional Equipment Selection, Energy Efficiency

We recommend the most suitable commercial kitchen equipment based on your cuisine type and daily operational needs, covering a full range of products including refrigeration/freezing, cooking, sanitation, and ventilation systems. Our equipment is not only highly efficient and energy-saving with stable performance but also meets safety standards, ensuring long-term reliable kitchen operation and reducing your business's operational costs.

Science-Based Equipment Selection Based on Operational Data. We don't just sell equipment—we analyze menus, average daily customer flow, and operating hours to recommend the optimal equipment combination.

Our selection criteria include:

Capacity Matching: Avoid equipment shortages or wasted investment.

Energy Efficiency: Prioritize energy-saving equipment to reduce long-term costs.

Brand Reliability: Provide comparisons of leading brands to balance performance and budget.

One-Stop Shopping with Comprehensive Categories

Cooking Equipment: Ranges, ovens, steamers, soup kettles, fryers, etc.

Refrigeration Equipment: Refrigerators, freezers, undercounter refrigerators, sashimi display cases.

Processing Equipment: Mixers, food processors, meat grinders, dishwashers.

Support Equipment: Ventilation systems, holding equipment, shelving/carts

Value-Added Services

Each unit includes detailed performance specifications, energy consumption data, maintenance cost analysis, and comparative charts to empower informed investment decisions.

Precision Installation & Commissioning, Safe & Reliable

Our experienced engineering team handles equipment transportation, installation, and professional commissioning. We meticulously control every installation detail to ensure optimal equipment performance. Whether for large central kitchens or small-to-medium restaurants, facilities can be rapidly operational without safety or operational concerns.

Standardized Installation Process

Pre-Installation Inspection: Verify dimensions, water/electricity/gas conditions.

Professional Installation: Equipment positioning, piping connections, electrical wiring.

System Integration: Multi-device coordination to ensure overall compatibility.

Safety Testing: Pressure, electrical leakage, and gas leak detection.

Comprehensive Commissioning and Acceptance

Performance Calibration: Adjust temperature controllers, pressure valves, and timers.

Operational Training: On-site guidance for kitchen staff.

Acceptance Documentation: Installation report, warranty documents, and operating manuals.

Commissioning Support: Initial production testing to ensure stable operation

Post-Installation Transition

Equipment records are established upon completion to facilitate maintenance and ensure seamless continuity.

Employee Training for Quick Proficiency

Following equipment deployment, we provide comprehensive operational training and usage guidance. This enables staff to rapidly master equipment functions and safety protocols, boosting productivity while minimizing losses and malfunctions caused by improper operation—ensuring seamless kitchen operations.

Tiered Training System

Management Level: Equipment Management, Energy Consumption Control, Maintenance Scheduling.

Chef Team: Equipment Operation, Cleaning Procedures, Fault Identification.

Support Staff: Daily Cleaning, Startup/Shutdown, Basic Maintenance.

Training Highlights

Safety Operations: Standards and Emergency Response.

Efficiency Enhancement: Chef Equipment Utilization Techniques.

Cleaning and Maintenance: Correct Methods and Frequency

Energy-Saving Practices: Guidance on Energy-Conserving Habits.

Training Outcomes Guarantee

Provides bilingual operation manuals, visual flowcharts, training certificates, and three months of complimentary phone support.

Regular Maintenance & After-Sales Service for Extended Equipment Lifespan

Long-term stable operation of commercial kitchen equipment relies on scientific maintenance. We offer periodic inspection, maintenance, and servicing to promptly identify potential issues, extend equipment lifespan, reduce repair costs, and ensure year-round efficient kitchen operations—allowing you to focus on your business without worry.

Preventive Maintenance Plan

Basic Maintenance: Monthly inspections, cleaning, and fundamental calibration.

Comprehensive Maintenance: Quarterly deep maintenance, component checks, and performance optimization.

Annual Major Maintenance: Full disassembly inspection, replacement of worn parts, and system optimization.

Smart Maintenance Management System

Digital Archives: Electronic health records established for each piece of equipment.

Early Warning Alerts: Automatic notifications for upcoming maintenance.

Remote Diagnostics: Rapid troubleshooting.

Spare Parts Inventory: Stocking frequently replaced components to reduce repair wait times.

Value of Maintenance Services

Reduce unplanned downtime by 70%.

Extend equipment lifespan by 30-50%.

Maintain equipment energy efficiency and lower operating costs.

Complete maintenance records improve sanitation inspection pass rates.

Our structured yet flexible process ensures your project stays on track, on budget, and meets your exact expectations. We believe in partnership and transparency at every stage.

Explore our extensive range of commercial kitchen equipment available for OEM and ODM projects.

We tailor every detail to your specifications.

How to Clean and Maintain a Cake Display Cabinet: Ultimate Guide for Bakeries & Cafes

View Details

Cake Display Cabinet Sizes and Dimensions Guide: Choosing the Perfect Showcase for Your Bakery

View Details

How to Choose Commercial Kitchen Refrigeration Equipment: A Complete Buyer’s Guide

View Details

ZKitchen equipment

High-performance quality kitchen equipment supplier

Innovative and durable kitchen solutions for chefs and foodservice businesses

Call / Email

+8618754395173

info@tzykitchen.com

Visit Our Office

China · Shandong Province · Binzhou Detailed Address